If you believe all the headlines, in a few short years or even less time, the way meat is grown will radically change. Brewing like tanks full of dividing cells will replace farms and factory farms raising livestock, thus no more animals will be slaughtered, all environmental issues- including climate change and water scarcity- will be resolved, world hunger will no longer exist, and deforestation will no longer be necessary. Plus best of all there will be meat a plenty that even die-hard vegans can consume with a clear conscience.

Okay, maybe this representation is a little bit of an exaggeration, but not by much. A lot of hyped up marketing spin is involved and has been expended to “position” lab meat, including re-branding it as “clean meat” (in vitro meat, cell meat, and cultured meat all didn’t do as well in marketing surveys). That hype involves creating a market for a product line that might otherwise only have a very limited audience and appeal. To build a market, consumers have to be dissuaded from consuming real meat. So to build an audience a whole litany of out of context statistics are repeated about water footprints, land use, feed efficiency, deforestation, greenhouse gases, health concerns, and animal welfare.

These stats raise some legitimate concerns, especially with specific forms of production (e.g. CAFO’s), though a lot of this very glib analysis is omitting contradictory information that also has to be taken into consideration. Such a glib marketing pitch also fails to mention a few significant issues or shortcomings with cell Ag. First, the replacement of an all in one product, livestock (that provides meat, fat, leather, and a myriad of other by-products) with a series of items have to be produced separately in their own bioreactors. Second, none of this lab meat will regenerate soil or have any soil health benefit. Third, a food (livestock meat), that can be raised on non-competitive food stuffs will be replaced by a product (lab meat) that’s growth will most likely rely on foods humans can consume. Fourth, labs with bioreactors to produce large quantities of cellular protein will need a lot of non-intermittent energy, so here too you’re taking a product like grass fed/finished beef that can be produced primarily with solar energy, and replacing it with a product grown in a medium that has to be kept at 98 degrees F in a sterile conditioned environment needing a non-intermittent source of energy for electricity. Furthermore, fifth, simply using industrial Ag differently doesn’t reduce collateral damage to the wildlife in ecosystems. So death isn’t somehow magically eliminated from the production of a cell Ag meat product.

At this point, it should also be noted that what really motivates a lot of this hype and pursuit of lab “meat” or cell Ag is a return on investment [ROI] for venture capitalists and billionaires via patents and intellectual property rather than any real genuine environmental or health concerns. Again a lot of this concern is green washed product placement for market share

When exploring these five just mentioned points in more detail, it helps to look at these five items in the context of the various arguments listed above (water, GHG’s, etc) currently being used to persuade consumers to accept these lab grown proteins as a viable alternative. As well as how these arguments will be used to try to persuade consumers to eat lab grown proteins in the future. When doing this exploration, one needs to differentiate between different production and management methods. The strength of these various arguments, as well as the applicability of the stats used, in large part depends upon how and where the livestock is raised. In general, there are a wide array of ways to raise, grow or catch different plants or animals. These ways range from very bad to very good in appropriate or inappropriate environments. So often arguments and stats used for or against a specific food may apply to one way of raising, growing or catching plants or animals but not to another way.

Though, even before doing this analysis, a brief overview of how cell Ag is and will be done is required.

Currently biopsies, small tissue samples, are taken from live farm animals. Stem cells are extracted from these biopsies and then placed in petri dishes full of cell medium including growth factor. The stem cells replicate in the petri dish and develop into small strands of muscle tissues. The petri dishes have cell media that contains the “food” that the cells need to grow. This media include sugars, amino acids, salts, minerals and growth factors. The growth factor are cytokines. Cytokines are a broad category of proteins that are important in signaling cells to grow and divide. Currently fetal bovine serum [FBS] is used as the growth factor, which is problematic on two counts. FBS is expensive and it comes from dead fetuses of cows. So it’s not exactly vegan. FBS also contains a complex array of proteins so it’s not something easily reproduced. Companies have been developing growth factors from non-animal sources, like from mushrooms, but they’re not as effective. Plus these vegan friendly GF’s are proprietary trade secrets that ultimately will be patented. So cell Ag companies really haven’t been disclosing what these plant derived GF’s are. As the stem cell divide and grow, the food needs to be constantly supplied while waste materials need to be removed. The growing splitting cells’ waste includes lactic acid and ammonia.

Now currently all these stem cells are grown in petri dishes filled with CM/GF into strands that are then assembled into a ground meat product like a burger or ball. Steak really isn’t part of the equation. Plus these are just muscle cells. Fat cells (adipose tissue) also need to be grown as well. These lab facsimiles are nowhere near as complex as beef from a steer or heifer. That beef includes muscle, adipose tissue, connective tissue, cartilage, and blood vessels. So lab meat isn’t as complex. Lab stem cells grown in petri dishes provide a proof of concept, but it’s a long way from being a commercial product that scales up to replace livestock, especially livestock raised in feedlots and CAFO’s. Scaling up isn’t easy and there are a lot of variables that impact costs, feed use, energy use, and water use.

Much of the underlying technology originates from the medical world to grow organs for transplants. Here containing costs and scaling aren’t major concerns. With large scale production of lab meat, people like Dr. Mark Post, the Dutch scientist who created a proof of concept “burger’, envision bioreactors that are 25,000 liters in size. One obvious problem with this vision is that no such bioreactors currently exist. The largest ones to date are around 10 liters. Typically, when companies discuss a lab meat future, they use beer breweries as an analogy, that is a large facility full of brewing tanks. There are a few problems with this analogy particularly the large bioreactors are full of dividing growing cells that need circulating fluid to provide more food for the growing cells and to remove waste. This food and waste are respectively the cell media and growth factors, that need to be replenished as well as the ammonia and lactic acid that need to be removed, as described above. So this is a lot different from a fermentation process that occurs with brewing beer.

In addition to bioreactor sizes, efficacy of non-animal based growth factors and scaling, there are other technological hurdles to overcome as well as a lot of unresolved questions. There are also a lot of work arounds. For example, with limited bioreactor sizing, a different “home brew” model has been proposed. This is a decentralized system where rather than having large central production facilities, there are a lot of smaller ones spread around. This type of solution though presents other problems, especially in regards to regulations. Despite being billed as “clean meat,” there is opportunity for the growing cells to be contaminated. So how this cell Ag industry is regulated still has to be figured out. There are issues too with how or if genetic engineering will be involved. Stem cells can only divide a certain amount of times. Though “immortal” lines, that can keep dividing, are possible. It’s easier to develop consistent immortal lines through genetic engineering, so the industry really lends itself to such genetic engineering, though already wary consumers, especially in Europe, may be even less accepting of consuming GMO lab meat than regular old lab meat.. Then too water and energy usage are large issues. Can water be filtered and recycled? An Israeli company is trying to do this. But, in general, getting questions answered by cell Ag companies isn’t easy to do. Numerous questions, for this article, sent to researchers at institutions, cell Ag companies, and universities were perfunctorily responded to with marketing speak, that is if they were responded to at all. So much of this industry is about intellectual property that many people in it aren’t exactly forthcoming with any of their research to date.

Looking closer at water usage, let’s first look at some of the metrics used by the cell Ag industry to dissuade people from eating meat from livestock, specifically beef, namely how many gallon of water is required to produce a pound of beef. The 1800 to 2000+ gallon number is cited without any real understanding of how this number of gallons is derived or what the number actually represents. Previously in the blog entry, Understanding Numbers, how water footprints are derived is described in some detail. To begin with, approximately only 1% of a water footprint number is drinking water consumed by a head of cattle. Plus, in short, for grass finished cattle, 97% of a water footprint number is green water, which is mainly rainfall. Three percent is blue water used for irrigation. Blue water is what’s critical. Many crops, including those needed for amino acids and sugars in the cell media for lab meat, require MORE blue water than grass finished beef. With grain finished meat, approximately 87 to 93% of the water footprint number is green water.

Whether meat is grown as livestock on a farm or in a bioreactor, green water or rain still falls. The real issue is how to best retain and utilize that rain fall. This comes down to appropriate land use as well as restoration of soil health. Most places in the world where beef cattle is raised is on land that isn’t arable for intensive or any form of crop production (only 6 to 7% of global beef cattle inventory is in the Amazon). Cattle, whether finished on grass or in feedlots can be useful tools for land regeneration for portions of or their entire lives. This land restoration, including restored soil health, increases water retention. Tilled annual organic and chemically input intensive conventional Ag leads to further land degradation which results in less water being retained. Again, counter intuitively, well managed grazing improves the hydrologic cycle whereas many forms of crop production undermine this cycle.

Now let’s compare this actual real world usage for beef cattle to a cell Ag grown stem cell protein. Two life cycle analysis [LCA] studies have been done comparing lab grown stem cells and meat from livestock. Both were done by Hanna Tuomisto (Tuomisto et al 2012, Tuomisto et al. 2014). The first in 2012 compared water footprints including green water use and the second in 2014 compared water footprints accounting for only blue water use. Of course, the cell Ag industry cites stats from the report including green water (rain fall) since these are the more dramatic numbers. Both LCA’s gather their data from Worldfootprint.org and use global averages that don’t differentiate too much for different methods of production. So all the data is constrained by the limitations of existing data used in water balance models, for example, like not knowing the soil type or health in specific regions or for not accounting for poly crop systems. Both reports also have assumptions or different scenarios as to where all the amino acids and proteins in the cell media come from. Since most of a water footprint number is the amount of water needed to grow crops for feed, there are assumptions and scenarios as to what’s being used as feed to feed the growing lab stem cells as well as how much feed is needed. These assumptions impact the water footprints for the lab meat. (Actually the entire LCA’s are largely based on assumptions since no large scale bioreactor facility existed at the time these LCA’s were done). Using wheat for amino acids and carbs takes less water to grow than corn. Algae is another option, though what’s not mentioned is the difficulty scaling algae production. Producing enough algae outdoors in sunny climates to meet the demand of scaled up lab meat may be problematic. Especially with investors like Cargill – a large soy bean grower- involved, the amino acids will more likely come from industrially farmed soy beans and the carbs from industrially farmed corn (HFCS) or wheat.

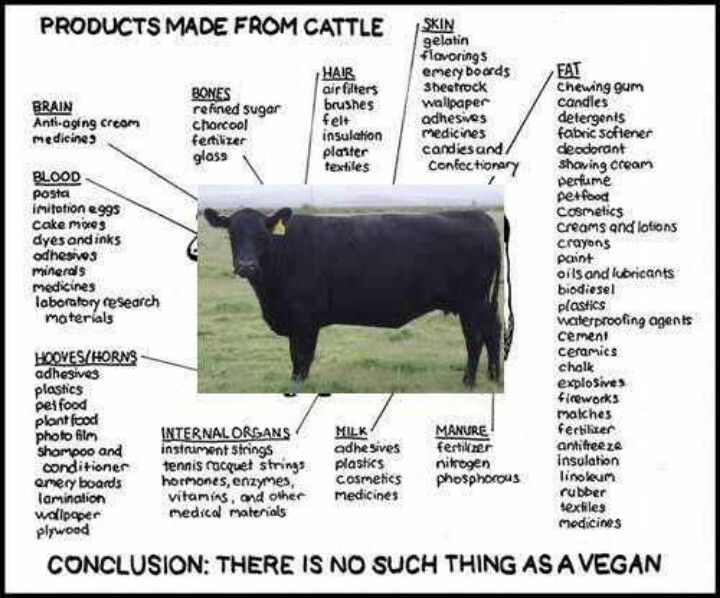

Another issue with the Tuomisto’s LCA’s is that they are only comparing lab meat stem cells to meat from animals. But with beef cattle, as previously noted, meat includes fat and connective tissues, so to get a more realistic burger bioreactors for these other components may also be needed. So that’s more water. Cattle also provide more than one product (see the attached image). Aside from more obvious co-products like leather, cattle provide a whole myriad of items that are used in numerous industries. So to make leather, another bioreactors full of circulating water based cell media will be needed. Other substitutes for cattle by-products may require other materials, bioreactors or other production methods that also require a lot of water. So a true comparison of lab meat to meat from livestock would be more comprehensive and include a more extensive framework to better understand the implications of transitioning from a systems with an all-in-one livestock animal (with meat/fat and by-products) to one of separate components all of which may need to be grown separately.(Mattick at al. 2014). With more bioreactors circulating a lot of blue water, it’s quite possible that well managed livestock on pasture use considerably less blue water than lab grown meats.

The are a few huge variables here including how long the various cell Ag products take to grow, and whether or not the water for the cell media can be recirculated. The longer it takes to grow the meat, the more feed in cell media and blue water is needed. Lactic acids and ammonia produced by the growing cells has to be removed from the water, so if this can be done and the water recycled, that makes a big difference too. What becomes of all that waste? Possibly fertilizer? But nitrogen based fertilizers aren’t exactly the most sustainable product. Nitrogen in manures are better utilized by plants. Most synthetic nitrogen is leached.

But I digress. Right now there are just more questions than answers with this technology. And because of intellectual property (IP) concerns, no one is very forthcoming with answers.

Different management of cattle also has different impacts on the soil. Cattle that continuously graze tend to over eat certain plants resulting in land and soil degradation. In contrast cattle that are well managed in adaptive grazing systems, where the cattle are frequently moved, leaving sufficient root mass, increase carbon sequestration. This increase, improves soil structure though soil microbial use of exudates. Then, this in turn, improves water penetration and absorption. Thus, when rain falls, more of that water is retained and utilized, In crop systems, especially industrial or tilled systems, the soil biology is reduced or killed, and there’s a lot of compaction. Rain fall thus tends to run off rather than be absorbed by the soil. So in other words, well managed cattle improve rain fall utilization while crops- used for the amino acids and sugars in cell media in the cell Ag bioreactors- don’t. Well managed beef cattle improved soil and the hydrologic cycle while cell Ag just further degrades those cycles making the land less drought resistant. Cell Ag is just using industrial crops differently. It doesn’t improve or change those industrial practices.

Now let’s move on to the land where all the green water falls. When stats are bantered about that livestock use 70% of the earth’s land mass, the small percentage of land that’s actually arable is usually the first stat omitted. There’s more land that’s suitable exclusively for grazing than is suitable for growing crops. The new UN FAO report on feed (Mottet et al. 2017) breaks down agricultural land usable for crops and not suitable for crops as approximately 33% (684.9 million hectares) of that Ag land being suitable for crops and 66% (1260.4 million hectares) of land not suitable for crops. Then there’s another 1.5 billion hectares not suitable for crops or livestock. Some of this land can be reclaimed with regenerative grazing. When citing the 70 percent figure, the assertion is also made that commodity crops like soy and corn are exclusively grown and used for animal feed. They aren’t. Over 90% of soy beans are pressed for oil. This oil ends up as cooking oil, biofuel or as industrial products. Soy meal goes mainly to feed chickens and then pigs in CAFO’s. With corn too, ethanol is a large co-products as are a wide array of food and industrial products like corn flour, HFCS, corn oil, Styrofoam and biodegradable plastics. With both corn and soy different portions of the beans, kernels and plants go to different products or uses. So in other words, the land area for these crops can’t all be exclusively attributed to animal Ag. More precise accounting is required.

Additionally a lot of grazed range land can be shared with wildlife. With certain forms of grazing management (e.g. regenerative, AMP or holistic management), grazing livestock only occupy a small portion of the land at any one time. Less than one or two percent of the land. So a 1000 acre cattle ranch will have cattle only on ten to twenty acres, if even that much, of that land at one time. Ranches managing in such a regenerative way function to maintain open space, and are basically creating nature preserves full of insects, birds, and other wildlife including predators when predator friendly strategies like livestock guard dogs are used.

Land that’s cropped on the other hand with conventional monocrops or organic row crops don’t have this dual usage. Though much of the earth’s arable crop land can also be mixed or integrated systems where BOTH livestock AND crops are raised. This adds further ambiguity to land use stats. When cropland is integrated with livestock, this also reduces the need for synthetic fertilizers as well as herbicides since livestock can graze cover crops and crop residues. To better understand this system of management, watch part five this Gabe Brown video below, The Keys to Building Healthy Soil.

The feed efficiency, or actually inefficiency, argument is based on the argument that it takes a lot more (6 to 20 ) kilograms of food to produce a kilogram of meat, especially beef. What this argument always fails to differentiate is food that is edible for humans and food that is not. When this distinction is made, the feed efficiency argument falls apart especially again for pastured beef cattle. Beef cattle and ruminants eat cover crops, and residues in integrated systems, by-products in landless systems, and numerous different kinds of grasses and forbs in cow/calf, stocker and grass finished systems. These are plant sources of food that humans can’t digest since we lack the microflora to digest cellulose. The UN FAO Report on feed (Mottet eat al 2017), Livestock: On our plates or eating at our table? A new analysis of the feed/food debate, discussed this issue in detail and noted that “cattle need only 0.6 kg of protein from edible feed to produce 1 kg of protein in milk and meat. Cattle thus contribute directly to global food security.” Cattle up cycle low quality and inedible food into nutrient dense protein that humans can consume

Cattle are eating grasses, by products, residues….so replacing a product that up cycles inedible to human food with one growing in a bioreactor consuming a lot of soy meal for amino acids, that could be soy flour for humans, decreases food security rather than increases it. For pigs and chickens as well as growing stem cells in bioreactors, feed could be insect based. This would provide proteins (amino acids) though would be problematic for cell meat protein since then the lab meat wouldn’t be vegan, But then again if the intent is to replace factory farmed livestock, specifically with facsimiles that don’t require so much death, rather than being strictly vegan, insects may be a more viable source of amino acids for cell media.

But what about greenhouses gases? Certainly livestock Ag by some accounts contributes up to 51% of greenhouse gases into the atmosphere. Well, to begin with that 51% discussed here in this blog entry, Does animal agriculture account for 51% of GHG emissions, is a very contrived bogus figure. The number generally cited is from 2013 UN FAO report at 14.5%. This number superseded the 2006 long shadow report, and differed from the IPCC’s numbers because both the 2006 and 2013 numbers included land use change as part of its life cycle analysis [LCA] The 14.5% does have some issues, namely for deforestation, it still used near peak 2005 rates only from OECD countries (those in South America, not Africa or Southeast Asia). The 14.5% number also didn’t accounted for any land use change for grassland to cropland as well as for any carbon or methane sinks since such data wasn’t easy to obtain. Thus using only the data it had impacted its accounting. Neither the 2006 nor the 2013 number do an LCA for other sectors, so the often repeatedly sentence from the 2006 Long Shadow report that emissions from animal Ag exceed those from transportation is incorrect. That 2006 report borrowed its transportation data from the IPCC that used only the tail pipe emission info from the transportation sector and wasn’t an LCA. So the correct statement, assuming the underlying number are correct, is that the animal Ag sector in its entirety, excluding any mitigation from sinks and attributing most land use change to the animal Ag sector, exceeds just the tail pipes emissions of the transportation sector.

Regardless, animal Ag does have a footprint, and cattle emit methane via the process of methanogenesis. This processes are well documented and the emission data has been extrapolated as well as repeatedly referenced to in a number of studies. In the world of atmospheric greenhouse gas science, what’s the easiest to measure typically gets the most blame. So blaming ‘cows” in films like Cowspiracy has been all the rage, and a useful recruiting tool for vegan jihadists. Here too the cell Ag industry, practically in sync, proclaims the superiority of its products partly due to a reduction of emissions and other stats similar to those used in such vegan films. The synchronicity of all of these efforts, gives the conspiracist in me the feeling that some of the timing of the release of these films was coordinated with the push for mock & lab protein replacements. After all spokespeople like the dentist Richard Oppenlander have ties to the industry. Oppenlander founded a mock protein company called Ope’s.

Conspiracies aside, whether with 2006 DEFRA or 2006 Long Shadow or later reports utilizing the data from these two sources, so much of the life cycle analysis for greenhouse gases emanating from livestock only has only looked at the emission side of the ledger, not accounting for any offsets from soil and atmospheric sinks for carbon and methane. Sinks aren’t as easily quantifiable. They’re also more variable. So data for sinks isn’t easily to model or extrapolate. As noted in my last blog entry, “Ruminations: methane math & context”, much of the discussion and science concerning enteric methane is both reductionist and driven by industrialists who use their reductionist science to legitimize their intensified systems of production (i.e factory farms). A larger contextual framework for methane really hasn’t been researched. More research has recently been done demonstrating the capacity of soils to function as carbon sinks to offset enteric methane, but meat industrialists and ironically their vegan allies are working hard to debunk such notions. Another recent blog entry, “It’s the soil biology stupid“, details how these debunking efforts are rooted in old soil science paradigms.

Regardless, a lot of the more current top down isotopic analysis of methane- identifying sources of methane via carbon signatures- is indicating that rises in atmospheric methane have more do to with shale gas, coal bed gas, and conventional natural gas extraction than “cows.” So the real solution to climate change is to wean our society off of ancient forms of carbon (fossil fuels) as quickly as possible including so-called “bridge” fuels. Converting our sources of electricity to renewable sources of energy as well as developing better battery technology is what we all should be collectively pushing for instead of looking to replace pastured livestock meat requiring primarily solar energy with products that require a lot of non-interment energy to grow stem cells in heated bioreactors in conditioned buildings.

Yes, cell Ag is going to require a lot of energy. How much exactly is an unknown because, as previously noted, the bioreactor technology to scale production doesn’t really exist yet. How long it takes dividing stem cells to fully grow to product size is also a variable. As previously and just noted, why cell Ag takes so much energy is because all the cell media in which the stem cells grow has to be kept at a constant temperature of 98 degrees Fahrenheit in the bioreactors in the sterile conditioned buildings. There’s also up stream and down stream energy uses for growing and harvesting the crops required for the cells as listed above plus distribution.

How much greenhouse gas is emitted in these various steps? Well, a lot of that is going to depend upon how the crops are grown, and where the energy comes from plus how much infrastructure is required for the bioreactors, facilities, and energy sources. So there are a lot of variables with different corresponding outcomes as to energy use and emissions.

Note too, crops grown without animal inputs need synthetic fertilizers. Even many high yield soy bean crops use synthetic nitrogen inputs to increase yields along with phosphorus and potash (potassium) that has to be mined, transported, and spread on fields. These synthetic fertilizers thus all have associated energy and emissions that have to be accounted for in any life cycle analysis of energy and greenhouse gases.

Whereas with regenerative pastured livestock, and particularly with ruminants, the vast majority of the energy to grow grasses and animals is directly coming from the sun. Well managed ruminants in regenerative integrated systems with diverse covers, that include legumes, mow and compost those covers as well as crop residues plus spread these composted manures which cycle nutrients including phosphorus and potassium. Moreover, as this 2018 study, Impacts of soil carbon sequestration on life cycle greenhouse gas emissions in Midwestern USA beef finishing systems, by Rowntree and Stanley shows ruminants can be raised in ways that REDUCE atmospheric carbon dioxide despite the enteric methane they emit. Now, obviously in confined animal operations (CAFO’s), especially for pigs and chickens, this is a lot different because there’s still a lot of energy required for growing and transporting industrial crops as well as to power large warehouse buildings. Crops like corn use a lot of nitrogen, so there’s energy and greenhouse gases associated with planting, fertilizing and harvesting crops that are, in part, used for animal feeds in CAFO’s including feedlots.

So when you compare energy use and greenhouse gas emissions in life cycle analysis [LCA’s], you really also have to compare production methods and systems. Too often it seems, to date, the LCA’s generated by the cell Ag industry for comparing lab meat to more traditional meat production have been best case scenarios for cell Ag versus worst case scenarios for meat from livestock. So many of the metrics presented by the cell Ag industry to make their case, to say the least, are a bit disingenuous if not downright deceitful.

Now when you compare different production systems ,including cell Ag, in regards to impacts on wildlife and ecosystems, the results might be a bit surprising and counter-intuitive. Industrial factory farming systems, with industrial crops providing feed for confined animals, obviously are the worst of the worst scenarios. In this scenario you have the death of all the fields animals that occurs with crop production along with the death of all the harvested livestock. Chicken accounts for the most death through soy meal farming and the sheer number of dead chickens. For the United States per recent stats, of the 9.2 billion land animals killed for food in 2014, 8.8 billion of those land animals were chickens.

Now with cell Ag and lab meat, portions of the industrial crops are just used differently. You’ll actually have a greater need for these crops including for the seed oils, since more of those oils will be needed to replace animal fats. So here too there will be a lot of death for land conversion and cultivation as well as for crop protection, irrigation, harvest, storage and transport plus for fertilizer extraction. Organic crop land also involves many of these same steps, so plenty of death occurs in those plant Ag systems as well. The large livestock animals needed for meat no longer die, but plenty of field animals still do like gophers, squirrels, mice, rats, snakes, migratory birds, nesting birds, salamanders, frogs, turtles, rabbits, foxes, bees and millions of other insects. So it’s not like cell Ag with its stem cell proteins and other products will magically end death in the food production process. It won’t. Cell Ag will just lead to another layer of separation and disconnection from the food supply with the very mistaken notion that no animals were harmed.

Regenerative Ag solutions with pastured livestock on range land and integrated into no-till cropping systems can drastically reduce the amount of collateral damage to field animals. Well managed ruminants in such systems can actually regenerate land and restore ecosystem function, and thus increase, rather than decrease, biodiversity. This makes more land available that has a higher carrying capacity for both more ruminants and more wild life. Increasing the amount of land, increasing the carrying capacity of the land, and integrating livestock into cropping systems goes a long way to answering the proverbial question as to whether or not regenerative grazing systems scale. With current global inventory of ruminants, most are in integrated systems. Those in landless systems like the feedlot grain finished production in the US spend a half to two-thirds of their lives on grass before being transferred to feedlots. So beef production, unlike pork and chicken isn’t vertically integrated. Thus transitioning to grass finishing is possible especially if a lot of marginal grasslands, that have been destroyed for ethanol production from corn and sugarcane crop expansion, are allowed to revert to grasslands. So the “not enough land” argument often cited is a bit fallacious.

Well that’s probably true, at least, for beef cattle, sheep and bison. Replacing the volume of chicken production might be a different story. Though here if the real concern is lessening death and reducing environmental impact, the best solution may be one where the primary source for cell media feed is protein and carbs from farmed insects that have been raised eating food waste rather than any more grains. This may not be a vegan solution and may not be the most economical or provide the highest rate of return, since industrial chicken production is real cheap, but such a cell meat solution for white meat would dramatically reduce the amount amount of dead chickens as well as the the amount of land needed for soy beans (thus fewer dead field animals). Farming soy beans for CAFO’s chickens and pigs as well as seed oils, has been a large driver for deforestation. Land converted from pasture to cropland for soy, has displaced grazers and released a lot of soil carbon.

Maybe too some of emphasis of cell Ag can be redirected toward replacing cooking fats in addition to meats from monogastric livestock (pigs and chickens) . Such an emphasis could replace seed oils as well for palm oil. Here too this could help reduce the need for palm oil tree plantations that convert diverse forest into a monocrops. But deforestation is a very complicated topic. the main driver is maximizing profit from the land, whether that profit be from beef cattle, palm oil, coffee, acai berries, or numerous other crops. Again the primary feed for the cell media for such fats should be farmed insects eating waste products, not soy meal or grains. Though again, the energy and water use numbers have to make sense.

Other possible uses for cell Ag maybe specialty products like horseshoe crab’s blue blood that’s used for for the detection of bacterial endotoxins in medical applications. A cell Ag company, Sothic Bioscience, is already in the process of doing this. This isn’t a high volume product, and it’s priced accordingly.

As just described some meat, fats, and specialty applications may make some sense. Though when looking at all the parameters in the proper context, replacing beef and other ruminant meat with lab grown stem cells likely isn’t the best way to utilize cell Ag technology. Blue water use might be more, so might energy use, and replacing a food that can be raised on inedible to human foods with another lab synthesized one requiring more industrially grown feed that humans can eat directly seems kind of dumb. Rather for ruminant meats, the more logically thing to do is expand regenerative practices so cattle, bison, sheep and goats can be used to improve and restore land that’s degenerating and rapidly losing topsoil. For without fertile land and topsoil, it really doesn’t matter what dietary pattern you follow, because we’re all screwed.

.

References

Tuomisto, H et al 2012. Life cycle assessment of cultured meat production

Tuomisto, H.L. et al. 2014. Environmental impacts of cultured meat -alternative production scenarios

Mattick, C.S. 2014 A case for systemic enviromental analysis of culured meat

Mottet et al. 2017. Livestock: On our plates or eating at our table? A new analysis of the feed/food debate

Stanley et al 2018 Impacts of soil carbon sequestration on life cycle greenhouse gas emissions in Midwestern USA beef finishing systems

Ok . Never read such a thorough and fascinating analysis. THANKS. What is the growth rate of those synthetic meat cells compared to a real cow?

LikeLike

This piece of writing is truly a pleasant one it helps new internet people, who are wishing for blogging.

LikeLike

Whats your take on Calysta Feedkind methanogen derived source of protein …for. humans.

I assume that the mass doubling rate is far faster than any lab-derived cell growth meat.

LikeLike

Wasn’t aware of Calysta Feedkind. I’m most familiar with insect feeds for livestock by EnviroFlight having spoken with their business development person a few years back for an article I wrote that included info on aquaculture and another about eggs. I will take a look at Feedkind. However, like with Enviroflight, I’m more inclined to feed insects, etc to livestock/fish and eat the livestock/eggs/fish than eat the insects/etc directly. Though thanks for the tip. I’ll look into it for both livestock and humans.

LikeLike

You seem to have studied the issue in depth. Some of my favorite sacred cows have been tiped. But i reserve skepticism for you also and really need to explore the issuue more thoroughly.

You may also want to know that Pond (algae) has partnered with ADM to produce protein from waste CO2 and LED light.

How fast will this process be compaired to methanogen growth.?

LikeLike

They is a recent video from one of these cell Ag conferences where the person from the algae industry openly acknowledges scaling algae for a source of cell media protein and sugars will probably be impossible to do. That is producing enough algae as amino acids and carbs for a scaled up cell Ag industry. Scaling, in general, is a huge problem for many of these technologies. Production of algae is also regional. Some one else also suggested seaweed as another option, but the protein and sugar contentfor most forms of seaweed isn’t very high.

Plus with investors like Cargill, and has openly been acknowledged by people like Mark Post, the obvious and main source with be the left over soy meal and corn starches that are currently used in large part for CAFO and feedlot feeds. The soy bean oil, biofuel, ethanol, alcohol, industrial solvent businesses that uses the oils from crushing soy and corn aren’t going away. So companies like Cargill, which is a HUGE soy grower, still needs customers for its left over soy cake. Cell Ag is potentially (or theoretically) a huge willing customer that needs cheap amino acids and sugars.

Remember too that the soy bean oil crushing business preceded the CAFO animal industry by 20 to 30 years. What to do with all the left over soy meal from the crushing industry pretty much begot factory farming especially of chickens. Cell Ag as envisioned by most really is a stainless steel CAFO, with all the inherent problems of industrial farming still present. Personally I don’t eat any soy bean, canola, corn or industrially derived seed or soy bean oil crops as cooking oils or as fats. I don’t do this for both health and environmental reasons. These fats tend to be high in Omega 6’s and or also easily oxidize.

LikeLiked by 1 person